Efficiency Spotlight with Local Bounti

With a focus on regional food production and limiting waste, Local Bounti is able to grow produce year-round while proving sustainability standards can be achieved.

Founded in 2018, Local Bounti set out to remedy key issues present with our current food system, such as food waste, safety, and security. Expressed in its 2021 Sustainability Report, the team set out with a mission to “bring our farm to your kitchen in the fewest food miles possible” by delivering local, sustainably grown fresh produce. In 2020, the company opened its flagship greenhouse in Hamilton, Mont., and that is where the Local Bounti team began refining its craft of producing leafy greens and herbs with its hybrid technique that combines vertical farming with greenhouse growing, known as Stack & Flow Technology.

Local Bounti is dedicated to ongoing innovation aimed at minimizing its environmental footprint and achieves this goal transparently through yearly Environmental, Social, and Governance (ESG) reporting. “Transparent reporting serves as the cornerstone of trust in a company’s integrity. It’s not just a disclosure of facts, but a testament to a commitment toward openness. Reporting in this way demonstrates dedication to accountability and sets an example of the way the industry can advance to lead to standardization,” explained Local Bounti’s Chief Executive Officer, Craig Hurlbert. You can access Local Bounti’s most recent sustainability report here.

The recent years have been filled with growth both inside the original facility and across the country. Local Bounti has expanded from one to six facilities and currently serves over 13,000 retail stores. The company celebrated its fifth anniversary in August 2023 and has grand openings for two new facilities in Texas and Washington slated for Spring 2024.

”In 2023, we dedicated our resources to actively participate in an industry-wide collaboration aimed at enhancing transparency and standardization. Through our partnership with RII on the CEA footprint project, we take pride in propelling the cause of CEA data transparency to new heights.

Local Bounti Sustainability Team

Facility Highlights

| Location | Hamilton, MT | Carpinteria, CA | Oxnard, CA | Byron, GA |

|---|---|---|---|---|

| Climate Zone | 6B (Cold-Dry) | 3C (Marine) | 3C (Marine) | 3A (Hot-Humid) |

| Type | Greenhouse and vertical tiers | |||

| Crops | Lettuces and Herbs | |||

| Canopy Size (sq ft) *Across all 4 facilities | 14,749,412 | |||

| Lighting | Mixed LED & HPS | |||

Leverage PowerScore

To Establish Benchmarks

PowerScore reveals operational key performance indicators of facilities and crops, empowering producers to compare their operations against key performance targets and see year-over-year trends. Aligning with producers’ sustainability objectives, it standardizes resource impacts of energy, water, emissions, and waste to enable data-driven decision-making.

Interested in learning how PowerScore calculates KPIs?

Learn more from our glossary ⟶

PowerScore Key Data Point:

Waste diverted from landfill

Today’s food system experiences massive losses. From the production stage to reaching the retail shelves, and at the consumer level, both resources (i.e., water and energy) and food are wasted throughout the supply chain. In the U.S., one-third of the food supply ends up in landfills and incinerators, where food waste is the most common class of refuse in both disposal methods.1,2 With the growing need to reduce food waste in the U.S., innovative growers in CEA, like Local Bounti, are focusing heavily on changing the fate of their waste and setting reduction goals.

Looking for where to start reducing waste at your facility?

Learn more from the EPA’s Wasted Food Scale. ⟶

Focusing on Waste Diversion

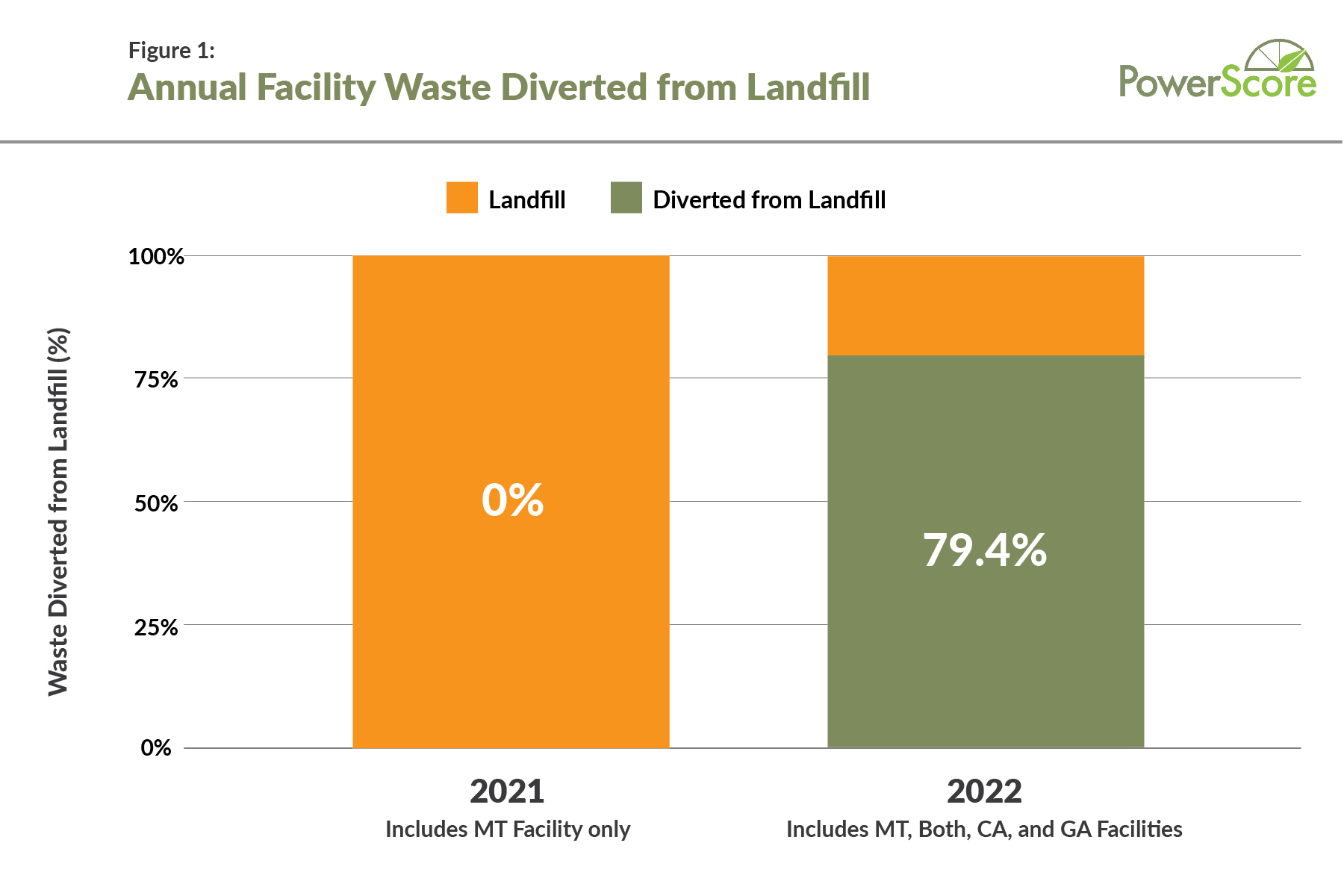

In Local Bounti’s waste accounting for its inaugural sustainability report, the sustainability team found that none of the waste produced at the Montana facility was being diverted. Aiming to resolve this, the team worked to refine on-site waste tracking to identify waste streams, primary sources of waste, and diversion opportunities.

Identifying organic waste (i.e., plant waste) as the primary contributor to production and post-production waste streams, Local Bounti searched for diversion pathways. Engaging with its community and other local businesses, Local Bounti created partnerships with farms using plant waste as animal feed and developed commercial composting partnerships.

Composting partnerships, however, have varied in scale and longevity, demonstrating the infrastructure complexities across the United States. At two facilities, Local Bounti has a commercial composting company that collects on a weekly basis, providing monthly pick-up billing that the sustainability team can use to validate the diversion. At another facility, compostable materials are given to a local master gardeners group which can only take a very limited quantity on an infrequent basis. As the sustainability team searches for a long-term solution, Local Bounti is gaining first-hand experience with the challenges producers can be met with when searching for a viable solution for waste diversion. With the expansion in 2022, Local Bounti took the lessons learned in Montana to its new facilities where the company continues to discover alternatives to waste management and diversion processes, such as packaging and cardboard recycling.

Local Bounti diverts nearly 80% of its on-site waste from landfills in 2022

Local Bounti considers the complex systems that are directly linked to the company’s waste footprint. Based on its processes, the team has separated waste into two primary groupings, Organic Waste and Non-Organic Waste. These groups are further broken into subcategories and are addressed by geography in alignment with the EPA waste management hierarchy, where source reduction is the ultimate objective, and continues its work to bring diversion up the productivity hierarchy.

This journey has not been a straightforward path, and the team has encountered setbacks along the way (like the time their compostable material deep froze into a 40-yard block of ice). Despite the headwinds, Local Bounti has found success. In its first year of focusing on the fate of on-site waste, the team successfully achieved 79% diverted from landfills, surpassing its commitment to achieve 50% diversion. Local Bounti is intentionally focused on this subject and plans to continue its waste diversion efforts across its facilities as it begins exploring ways to get more precise waste measurements occurring along the supply chain.

Helpful resources Local Bounti uses at their Facilities

Key Takeaways

- Identifying and tracking the waste types and streams occurring in a CEA facility are key steps in diverting waste at an operation.

- Waste diversion pathways can be difficult to discover and vary by region, but engaging with your local community can provide unique opportunities.

- Developing a foundation of standard operating procedures (SOPs), reduction strategies, and goals allows operations like Local Bounti to take the lessons learned to the new facilities.

Additional Resources

- Check out Local Bounti’s 2022 Sustainability Report

- Keep up to date with Local Bounti on its website