Controls & Automation

in CEA Facilities

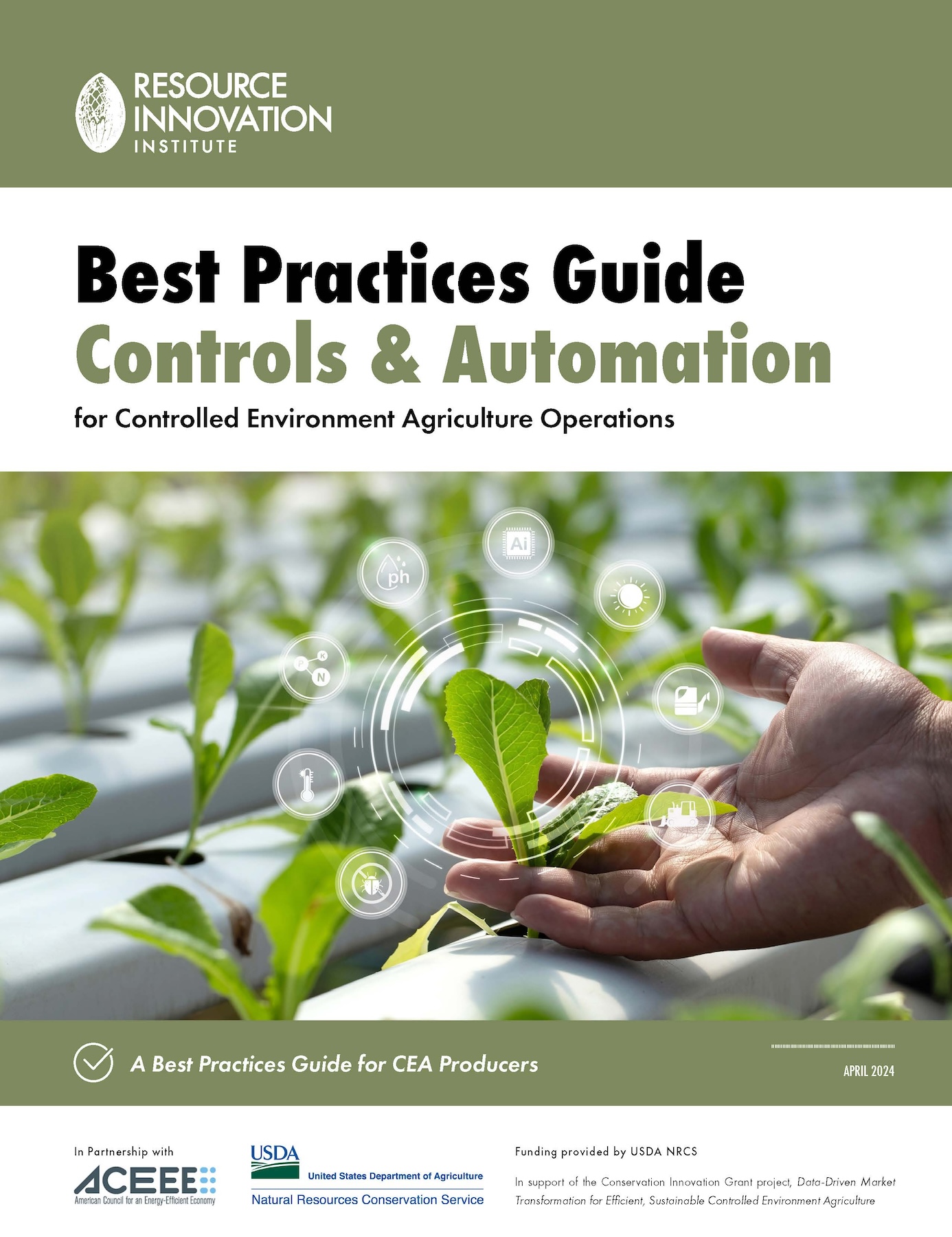

Developing best practices in controls and automation for controlled environment agriculture

As controlled environment agriculture continues to expand, so does the availability of technology to enable efficient operational production. Resource Innovation Institute is proud to start its next working group to develop best practices for indoor and greenhouse operators to consider as they integrate controls and automation into their facility design.

The Controls & Automation Working Group will advise on developing the Controls & Automation Best Practices Guide for CEA. The guide will be written and published by Resource Innovation Institute, available to producers for free download, and promoted and distributed by the USDA.

The collaborative Controls & Automation Best Practice Guide is now available!

Developed by a 28-member working group representing experts from CEA operators, academics, suppliers and equipment manufacturers across the industry. This guide is intended as a resource for those interested in first introducing controls systems to those looking to improve their operational efficiencies with their existing technologies.

Download the free report today!

”We are really proud to provide the latest in the best practice guidance on controls and automation. This could not have been done without the incredible contribution to our working group members. Most operators currently working in CEA facilities will see the value in these recommendations right away, while others may find some ideas for improvements they did not previously know existed. Our broader goal for the guide is that it helps those who are designing new facilities to include these important guidelines as a foundational component of their buildings, rather than an afterthought. The bigger objective is to encourage climate reduction from the beginning of the planning process.”

Rob EddyResource Efficiency Horticulturist

A Guide With An Action Plan

The emphasis of this guide is on using controls and automation to improve the resource efficiency of cultivation facilities by reducing energy consumption and peak loads, as well as water consumption.

The guide dives into the following topics while providing effective, actionable recommendations

for both large and small operations to save energy costs and decarbonize CEA operations:

- How CEA facilities use controls and automation

- Describing controls systems

- Data collection and utilization

- Climate-smart controls of temperature, humidity, and airflow

- Climate-smart controls of lighting and shading

- Climate-smart controls of irrigation systems

- Climate-smart controls of C02 enrichment

- Plant conveyance

- Machine-vision grading

The technical advisory council is composed of leaders in the CEA industry

Best Practice Guide Authors and Acknowledgements

Special thanks to the authors and contributing editors of the guide