Controlled Environment Agriculture presents specific challenges due to the need for precise temperature and humidity control throughout various growth stages. For facility operators, the goal is to create a consistent environment that maximizes plant health, yield, and potency, all while maintaining low production costs.

In both indoor and sealed greenhouse environments, proper dehumidification is critical in CEA cultivation to prevent mold, mildew, and other humidity-related issues. While HVAC and dehumidification systems can be resource-intensive, there are actions growers can take to ensure that their systems are running at peak performance and efficiency.

Here, we offer some expert, real-world-verified tips to help you optimize your CEA HVAC and dehumidification systems.

1. Perform regular maintenance

Most HVAC and dehumidification equipment lack monitoring systems. This means operators should be aware of the signs that their environmental control systems are no longer functioning at peak efficiency.

One potential sign that HVAC equipment might need maintenance is if operators notice reduced airflow. A drop in airflow could be a sign of clogged air filters, which can starve the system and reduce performance and efficiency.

When considering air filter replacements, CEA operators can look at a filter’s Minimum Efficiency Reporting Value (MERV), which indicates a filter’s effectiveness. As described in RII’s HVAC Best Practices Guide, “[the] higher the MERV rating, the smaller the particulates the filter can trap. MERV 11 to MERV 123 filters are recommended for CEA environments.” While high-value crop growers may believe the highest possible rating is best, filters with high MERV ratings can result in greater power consumption as fans will need to pull harder to move the air through the filter. Systems with electronically commutated motor (ECM) blowers are designed to handle the air flow restriction from the filter with little energy penalty.

Another HVAC component that needs regular maintenance is drain lines, says Randy Lenz, a senior application engineer with dehumidification and humidification systems provider Anden. Ensuring drain lines remain clean and unclogged will prevent water backup that can cause freezing, forcing your system into an energy-intensive defrosting mode.

Clogged drain lines can also be a perfect home for fungal and microbial growth. “The water that comes out of dehumidifiers in the HVAC basically is pure, and it grows microbials really quickly,” Lenz notes. Those microbes can form a biofilm on drain lines that can cause water to back up into the HVAC and/or dehumidifier systems. The microbial contamination can also make it more difficult for facilities to recycle and reuse that water.

To prevent microbial growth, Lenz advises operators to ensure drain lines are properly installed with correct pitching, eliminating standing water except for traps. (Adding unions to traps also allows for easy cleaning without affecting fertigation systems.)

It’s generally recommended to change filters and clean drain lines every time you harvest a room. That said, the frequency may vary based on the cleanliness of the environment and the specific agricultural operation.

Lenz has seen CEA operators use various antimicrobial solutions to clean irrigation and drain lines, but operators should be sure to follow all label directions when using disinfectants, as some may be at concentrations that are toxic to plants and/or not appropriate for CEA environments. Hydroponic-grown crops, especially, can be hyper-sensitive to common disinfectants. For example, a 2023 study found that chlorine levels in drinking water “can cause significant marketable yield reduction in lettuce grown in deep-water culture.”

Sanidate 5.0 is a suitable hydrogen peroxide- and peracetic acid-based product to use in a horticultural setting. Per the product label, “For irrigation water, apply 4.8 to 24 fluid ounces of SaniDate 5.0 per 1,000 gallons of water. This amount will provide 2-11 ppm of peroxyacetic acid.”

While some operators may turn to diluted bleach, it is generally not advisable as “[repeated] use of chlorine solutions may be harmful to plastics or metals,” according to a report by the University of Massachusetts, which also noted that “[chlorine] bleach is phytotoxic to some plants, such as poinsettias.”

2. Choose the right system size for your operation

A common mistake Lenz sees CEA operators make is not sizing their HVAC system to match their needs, whether that is having a system that is too small, or too big, with both having their own set of drawbacks.

RII’s HVAC Best Practices Guide notes that “Oversizing your HVAC equipment can result in higher energy use and short cycling, which can result in less latent heat removal and humidity control during cooling. Undersizing climate control equipment can be detrimental to CEA operations because target environmental conditions cannot be met, affecting plant health, and impacting canopy productivity.”

Lenz advises CEA operators to get their HVAC and dehumidification equipment provider(s) involved early in the design conversation to ensure that the appropriate systems are selected. When initiating discussions with HVAC providers, Lenz says CEA operators should come prepared with information about their plant count, lighting types, and water feed rates. This detailed information helps streamline the sizing and planning process.

Lenz also suggests operations use multiple smaller units instead of one larger system, noting that distributing the load across several smaller units (e.g., multiple 5-ton systems) offers advantages over a single centralized unit.

“If you lose 25% of your cooling capacity, like if an HVAC system goes down, you can turn your lights down to 75%,” to offset that load. “Then you have a day or two to get it fixed and you’re not scrambling. Whereas if you have maybe two 10-ton units in there and one goes out now, [operators] don’t want to turn [their] lights down that low, but [they have] all this heat to deal with and it’s a struggle.”

While the market is increasingly turning to combined HVAC-D systems, the upfront costs may not be feasible for every operation. Cash-strapped CEA growers can consider adding standalone dehumidification units in their cultivation areas to reduce the load on their HVAC systems. “Having the right amount of dehumidification in the room [and] getting that moisture out of the air makes the HVAC equipment more effective,” Lenz says.

3. Experiment with temperature and humidity ranges

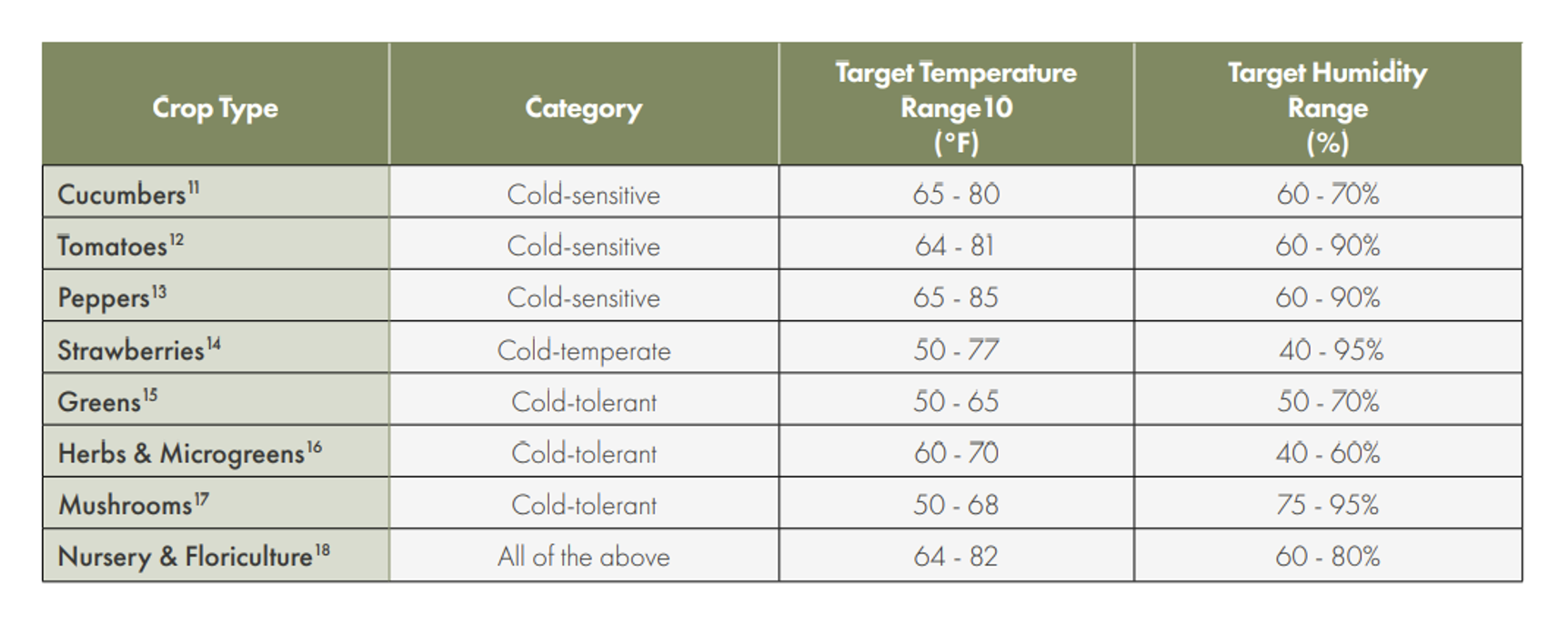

Another way to increase an HVAC system’s efficiency is to experiment with widening environmental condition ranges. While specific temperature and humidity settings are crucial for plant health, there’s often flexibility within these ranges. Experimentation with wider bands can reduce the workload on HVAC systems while maintaining optimal conditions for plant growth.

For example, “nighttime temperatures between 50°F-55°F are vital for strawberry production. Temperatures above 60°F can result in undesirable acidic flavors and drastic reduction in fruit yield,” notes RII’s HVAC Best Practices Guide.

For cannabis cultivators, reducing temperatures and humidity levels can also increase the development of desirable compounds and traits, Lenz notes. “Most people will say it is the stress of dropping that temperature at the end of flowering by five to 10 degrees and dropping the RH, making a colder and drier [environment] that brings out the [purple/pink] colors and brings out the oils. It’s not that I have to be 65°F to do that. I just have to drop it.”

Smart horticultural systems can help growers optimize HVAC equipment by staging units based on current environmental conditions. A slow and steady approach to controlling equipment during temperature and humidity fluctuations can lead to more consistent and efficient results.

4. Consider your building envelope

Well-insulated grow facilities with thick walls, such as those using well-sealed structurally insulated panels, metal insulated panels (MIPs), or spray foam insulation, minimize the impact of the outdoor environment in your cultivation areas. This is especially important for growers in climates whose temperatures fluctuate greatly.

For example, areas in the Midwest and the Northeast United States, as well as Canada, can experience severe cold snaps. These conditions can cause HVAC equipment to freeze if not properly insulated, Lenz says HVAC suppliers can advise what settings and intelligent systems can be used to minimize the risk of equipment freezing.

While there isn’t much operators can do to prevent the extra loads from heat waves or freezes, regular maintenance, monitoring, and having backup systems in place can help mitigate the impact of extreme weather on HVAC performance, Lenz says.

5. Look for rebates and incentives for high-efficiency systems

CEA growers using older HVAC and dehumidification equipment can explore government grants, rebates, and utility incentives to upgrade to high-efficiency HVAC systems.

States like Michigan and Oregon can offer generous rebates, Lenz says. However, state-specific programs vary, and some utility providers may not have programs for HVAC systems as they do for LED lights.

But just like how incentive programs for LEDs started with a conversation between industry stakeholders, CEA growers can attempt to negotiate custom solutions or advocate for new programs in their states. Engaging in conversations with HVAC providers and experts is crucial for identifying opportunities.

“The thing is to ask,” Lenz says. “Whether you’re talking to your HVAC people, your lighting people, your dehumidifier people, we are pretty much all aware of what is available in each state and can point you in the right direction.”

Meet Our Members

Thank you to our members who participated in this blog. Read more about their organizations below:

Randy Lenz is a senior application engineer with Anden. He has provided expert technical advice for humidity solutions for over 20 years. He started with Anden’s parent company Aprilaire as a Technical Support Representative, advising contractor technicians of installation procedures and best practices while they were on the job. Lenz has been relied upon for his expert knowledge of Aprilaire’s humidifier and dehumidifier products and environmental control. For the past 7 years, he has filled the role of Senior Application Engineer for Anden Consulting, educating and training cultivators and contractors in the humidity solutions in the United States and Canada for CEA applications.