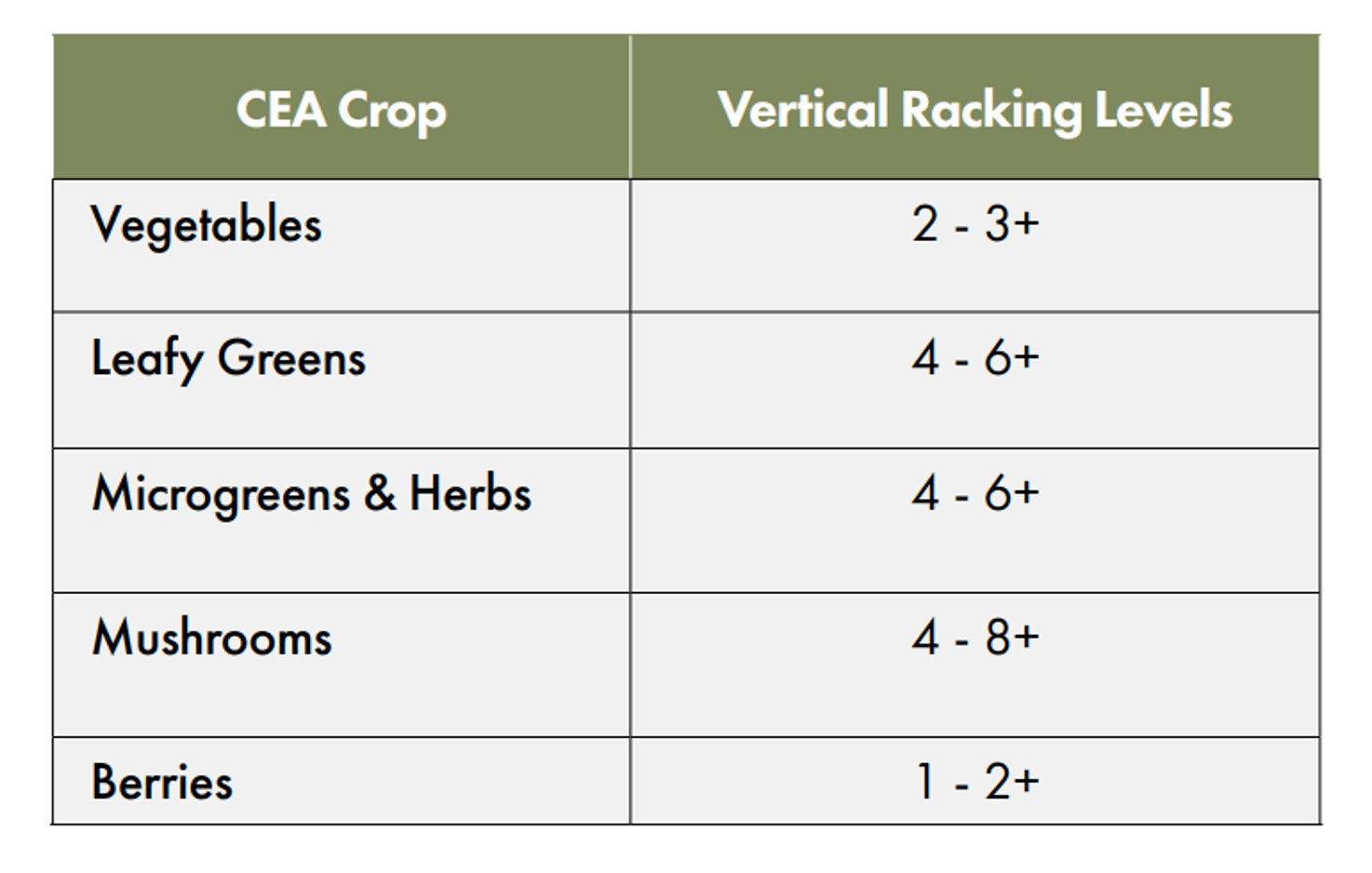

The pursuit of optimal crop yields and resource efficiency has led to groundbreaking innovations in controlled environment agriculture (CEA) facility design. The popularization of light-emitted diode (LED) fixtures in recent years has preceded a boom in vertical farming in both indoor and greenhouse environments. These tiered systems allow operators to maximize production by multiplying their cultivation canopy area.

One critical element that significantly influences the success of CEA operations leveraging vertical racking systems is airflow management. The efficient circulation and distribution of air within a cultivation facility play a pivotal role in maintaining optimal conditions for plant growth, health, and productivity.

Airflow design is an intricate process that interplays with lighting, irrigation, and environmental control systems. These tips will help CEA operators harness the full potential of vertical racking systems in CEA through improved airflow management.

1. Leave some breathing room.

Anders Peterson, Director of Horticulture at vertical and mobile racking system provider Pipp Horticulture, says one of the most common mistakes he sees at facilities he visits is operators, in an attempt to maximize revenues, “choking the room out” by not leaving space in front of, behind, and above the racks.

“No matter how many fans you put in that room, air is not going to mix and flow through that space when the canopy fills out,” he says. “You’ve just choked the room out with a giant hedge of vegetative plant material that no amount of airflow can penetrate.”

The amount of space needed around a vertical racking system will depend on a variety of factors, including temperature and humidity settings, transpiration rates, crop type, and lighting intensity, among others. Facility operators should aim to have enough space to allow the air to mix and homogenize.

Additionally, Peterson advises facility designers to avoid racks that span more than 40 feet in length–any longer and the air will have picked up too much heat and humidity. “The longer the row, depending on your airflow strategy, the harder it is to essentially maintain consistency from front to back,” he says.

2. Quantify your airflow.

While more and more indoor farm operators and greenhouse growers are tracking environmental data such as light intensities, feeding and irrigation rates, temperature, and humidity levels, one important metric is often left unexamined: airflow and airspeed.

“Airflow is the one parameter that when you pull up all these fancy automation and control platforms, you see all this data, but you don’t see airflow,” Peterson shares. By quantifying airflow, CEA growers can get a better understanding of their environment and energy loads.

Growers can start measuring airflow using a hot wire anemometer, a device used to measure air velocity and pressure. These devices are more accurate at lower air velocities (like those in a CEA environment) than a vane anemometer, which uses fans to measure the same metrics.

“I recommend grabbing one and taking a sampling of airflow velocities throughout your space and averaging it per row, per table, per tier–whatever you want,” Peterson advises.

Though many experts recommend an airflow of 0.3-0.5 m/s to remove the saturated vapor of the leaf boundary layer, Peterson has seen in practice that this may not be enough. In his experience, most greenhouse-grown crops will require an airflow velocity of up to 1 meter per second (up to 200 feet per minute), while leafy greens generally require a slightly lower velocity of up to 0.6 meters per second (up to 100 feet per minute) and cannabis requires up to 1.5 meters per second of airflow (up to 300 feet per minute).

“I have found with cannabis, because of the higher light energy input into the system, you also need a proportionally higher airflow velocity to balance these faster transpiration and photosynthetic rates,” Peterson says. “If you don’t have enough velocity, then you’re not going to uptake enough CO2 and you’re not going to wick that water vapor away from the stomata as they’re transpiring.

In veg, I typically recommend something around 100 to 150 feet per minute. In flower, anywhere from 150 to 300 feet per minute at the top of your canopy, depending on your PPFD. Generally, anything over 250 is not typically needed unless you’re running a PPFD of, say, 1,400-1,500 plus.”

3. Consider convection heat.

When considering integrating vertical racking systems in your CEA facility, it’s crucial to account for the added heat loads that come with a larger canopy surface. In a single-tier grow, rising heat poses less risk to crop health and productivity. However, that convection heat can lead to poor crop outcomes in a multi-tier facility.

“Without any strategic design of the space, you naturally get a chimney effect where heat from the lower tiers will naturally rise to the upper tiers and you’ll typically have an uneven distribution of the environment,” Peterson says. “To be successful in any commercial cultivation, whether it’s a vertical farm or greenhouse, consistency is key.”

CEA facility operators can optimize airflow by, for example, opting for gutter-style trays that break up horizontal planes. “That helps with that convective heat transfer, but still is not the only solution,” Peterson says.

4. Leverage both top-down and sub-canopy airflow.

Another way CEA facility operators can improve airflow and homogenize environmental conditions is by utilizing both top-down and sub-canopy airflow systems. Top-down airflow systems can be delivered through the lighting fixture, while sub-canopy air will be delivered from the tray or poly-tubes blowing air up. In Peterson’s perfect system, tiered grows “would have a combination of both: sub-canopy airflow at a lower velocity, and a top-down airflow system at a slightly higher velocity.”

Being able to toggle between top-down and sub-canopy airflow systems can help give the plants what they need when they need, Peterson explains. “In the earlier stages of flower, pushing CO2 up to the stomata during the stretch phase will maximize CO2 uptake and strengthen that plant” he notes. “Then, you can switch over to a top-down airflow to mitigate leaf temperatures, facilitate gas exchange, and help ward off mold and pest pathogens, towards the later flowering stages.” The top-down airflow also can reduce lettuce tip burn, according to research presented in Biosystems Engineering.

“I see an argument to have both a bottom-up and a top-down airflow delivery. But none of this matters if these systems don’t work in conjunction with your HVAC and dehumidification design.”

5. Integrate your airflow and HVAC systems.

The greatest limiting factor to profitability and success in vertical farms, Peterson says, is the integration of airflow and mechanical system designs. “I often see engineers who are still new to this application design a supply and return configuration of their HVAC systems as if it’s a single-level room, … and that simply just cannot be the way we do it,” he stresses.

By considering HVAC latent and sensible load sizes, equipment spacing and design, ductwork, air velocity, and its flow through the room, facility operators and their partners can work to optimize and integrate all environmental control systems, allowing each separate system to work in conjunction with the others rather than against.

“When you see a really well-designed system, the yield potential of the space goes up,” Peterson says. He also highlights the importance of thinking about this early in facility design, as mechanical and airflow systems can be the hardest to retrofit, “So it really behooves you to get it right the first time.”

For facilities ready to develop an advanced airflow control system, Peterson recommends integrating anemometers and other airflow sensors into the canopy and tying those to a centralized control platform. For example, operators can opt to use electronically commutated (EC) fans instead of traditional systems. EC fans are more energy efficient and offer precise variable speed control. This way, operators can have “a computer control the EC fan motor so that it’s varying the speed of the fan to maintain your ideal air velocity without wasting energy based on sensor feedback.”

Operators on the bleeding edge of resource efficiency can even work to integrate the HVAC system directly into the in-rack airflow system. By ducting these systems directly into the vertical rack system and delivering the airflow so close to the canopy, CEA growers potentially reduce their HVAC loads and system sizing requirements, Peterson adds.

By embracing these insights and prioritizing the integration of airflow and HVAC systems from the early stages of facility design, the path to a more resource-efficient, profitable, and successful vertical farm becomes clearer than ever. Remember, in the hunt for elevated crop performance, every breath counts.

Meet Our Members

Thank you to our members who participated in this blog. Read more about their organizations below:

Anders Peterson is Director of Horticulture at RII member Pipp Horticulture, a designer of mobile vertical grow solutions.