Working with living organisms requires a careful balance of resource efficiency and crop quality, yet controlled environment agriculture (CEA) companies are under constant pressure to reduce resource use, minimize carbon footprints, and taper costs.

By optimizing the environmental parameters within CEA facilities, indoor farm operators have the opportunity to significantly reduce the burden on HVAC-D (Heating, Ventilation, Air Conditioning, and Dehumidification) systems, and greenhouse growers can minimize the use of other resource-intensive technologies.

By both adopting advanced technologies and data-driven solutions, growers can optimize CEA environments to achieve a harmonious ecosystem where crops flourish while reducing energy consumption and waste.

Download Resource Innovation Institute’s HVAC Best Practices Guide here for more information, expert insights, and tips on everything that goes into creating an efficient and productive HVAC-D setup for CEA facilities.

Expand Temperature Ranges

The crops an operation grows–whether cut flowers, produce, or medicinal–ultimately determine the target temperature ranges it needs in its cultivation spaces. In greenhouses, mechanical systems are designed to best keep the environment within that optimal band.

“The plant that you have drives what type of environment that you’re in,” says Jeff Neff, Senior Technical Lead at RII member Argus. “For example, Kwantlen University (KPU) designed these Venlo-style greenhouses: a tall greenhouse, roof vents only, no exhaust fans or pad systems. That type of greenhouse is designed for vine crops, meaning peppers, tomatoes, and cucumbers. The idea with the vine crop is … they grow tall. In that way, they are part of the cooling system” by evapotranspiration.

When growing non-vine crops in that structure, KPU struggled with cooling, Neff explains. “[When] you have a small plant in a tall greenhouse with roof vents, it’s going to be very hot in that greenhouse and the ability to cool it is going to be very difficult, so you may have to add a misting system or something to actually lower that temperature.” (KPU addressed the cooling issue by adding a misting system.)

One strategy to consider to balance the added energy used from cooling during hot days is to let temperatures drop slightly below usual targets. “The idea is that my plant has been over temperature for the last three days, so I can afford to drop that temperature a little bit at night,” Neff says. By avoiding warming an already overheated crop at night, operators can reduce their facility’s energy use.

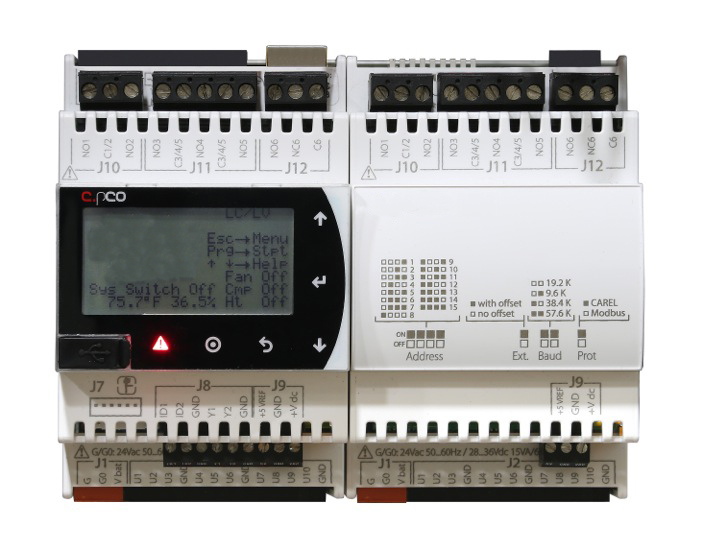

Neff also suggests that both indoor and greenhouse operators avoid setting their control systems to small ranges, as doing so can cause systems to cannibalize one another. “You want to have your targets a minimum of two degrees Celsius apart,” Neff says. For example, having cooling pads turn on immediately after the space has been warmed to optimal temperature will create temperature swings that waste both power and water.

“Same goes for humidity,” he adds. “You want to make sure your dehumidification and humidification targets are relatively far apart so they don’t interfere with each other.”

VPD is Key

Vapor pressure deficit (VPD) is a measurement that indicates how dry the air surrounding the plants is. Low VPD means the air is nearly saturated with moisture, leaving little room for the air to take on additional water. High VPD means the air is very dry and has ample room to take on additional water. Cultivators can control how quickly plants transpire by monitoring and manipulating VPD levels.

Plants need to replenish the water they give off through transpiration. As plants transpire, their water and nutrient uptake through the roots increases. “By controlling VPD and regulating plant transpiration, cultivators can control the plant’s metabolic functions, potentially maximizing the expression of certain desirable qualities and dramatically influencing the overall value of the crop along with overall yields,” Chip Seidel, CEA Manager at RII member Desert Aire, says.

Cultivation area humidity fluctuations are mainly driven by irrigation events and crop evapotranspiration rates. As defined in RII’s HVAC Best Practices Guide, “Evapotranspiration (ET) is the process adding together water vapor from transpiration and evaporation in your cultivation spaces that your HVAC equipment must manage to maintain environmental conditions.”

Sizing HVAC-D Systems

HVAC-D units are more commonly used in indoor farms than greenhouses (although some hybrid/mixed-light facilities may have HVAC-D technologies). When determining your HVAC-D system loads, it is important to account for the impacts of ET which is closely related to VPD. The higher the target VPD the more moisture will be transpired, which increases loads. In addition, it is important to remember that HVAC-D systems in general are more efficient at removing moisture at higher temperatures.

For this reason, a full load analysis should be performed based on target room conditions, canopy size, lighting load, watering rates and several other important variables prior to selecting any HVAC-D equipment. “Cultivators and engineers should work with HVAC-D equipment manufacturers that design equipment for indoor cultivation and have a robust sizing tool to build out load models of both the latent or moisture and sensible, or heat loads,” Seidel says.

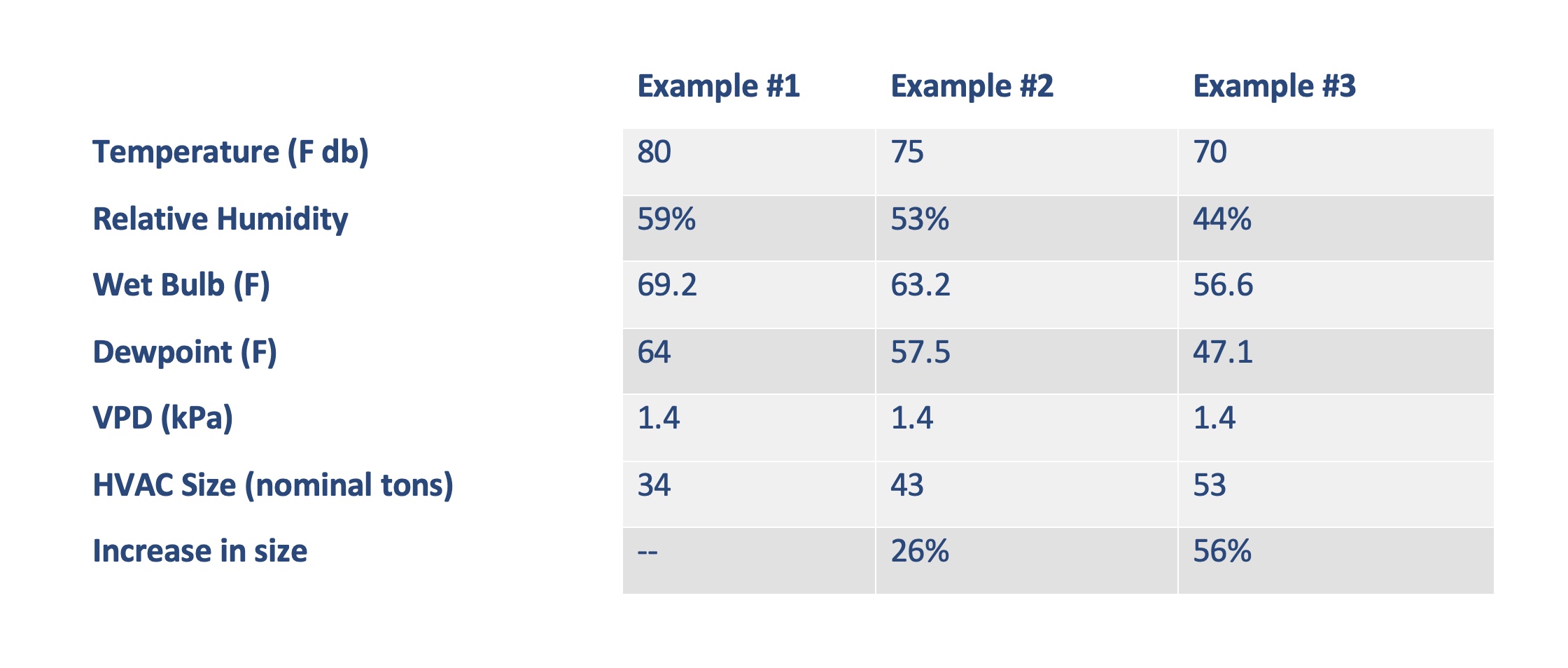

Higher Temperatures, Same VPD

The same VPD level can be maintained at different temperatures and humidities. Because HVAC-D units are more efficient at pulling moisture from a warmer environment than a cooler one, CEA operators can consider setting slightly higher temperature targets to potentially reduce their HVAC-D size needs. (See table for more details.)

Additional Tips

Avoiding microclimates is important to the proper functioning of your HVAC-D equipment and the quality of your crop. A homogenized environment minimizes the risk of pathogen outbreaks and maximizes yield.

RII’s HVAC Best Practices Guide suggests CEA operators ensure “consistent spacing of circulation and ventilation equipment” to avoid microclimates forming. Additionally, “greenhouses should strive for minimal temperature differences between the intake and fan (exhaust) ends of greenhouse bays to maintain little temperature variation across cultivation spaces.” Meanwhile, indoor farms should “consider how HVAC systems will reach every level of tiered racking systems and how stale areas will be removed at the ceiling to counteract stack effect.”

RII’s HVAC Best Practices Guide also outlines that greenhouses “and indoor farms can both apply thermal storage technology to use energy when utility costs are lower and save it to use during more expensive times of day.” For example, CEA facilities “can use tanks to store cold water in the summer and hot water in the winter to lower and shift peak HVAC demands to different times of day to take advantage of excess thermal energy when it is available.”

Neff also advises CEA facilities to not have too short transition periods between day and night settings. “We want to slowly transition between the day and the night, or whatever additional periods. If you do it too quickly you are shocking both the plants and the equipment. … Putting [a transition period of] one minute, or two, or a few minutes will definitely create excessive equipment and energy use. And potentially it could be detrimental to the crop.”

By diligently optimizing the environmental conditions within their facilities, CEA operators can redefine crop production through maximized energy efficiency.

Meet Our Members

Thank you to our members who participated in this blog. Read more about their organizations below:

Jeff Neff started his career at Argus Controls 1994 as a senior application technician. He helped Argus customers with Systems Design and Integration, Climate Controls, Irrigation, Fertigation, Lighting, CO2, and custom process control applications.In October 2020, he became the Senior Technical Lead at Argus to provide technical leadership to all Technologists, Technicians and Designers.

Chip Seidel has 15 years of experience working in a leadership capacity for manufacturers of specialized HVAC equipment serving unique and challenging industries. For the past 6 years Chip has been solely focused on the indoor agriculture sector, working closely with cultivators and engineers to design the optimal systems for plant growth, while minimizing energy usage and maximizing overall system reliability. Chip holds an undergraduate degree in Economics from Grinnell College, and an MBA from the University of Wisconsin, Madison.