Controlled Environment Agriculture (CEA) is intimately connected to the responsible management of our most valuable resource: water. CEA enables us to cultivate crops efficiently regardless of external factors such as weather and location. However, this advancement comes at a cost, with water usage playing a pivotal role in the equation.

Water scarcity often is a regional phenomenon, but water efficiency efforts are a collective endeavor the CEA industry needs to begin taking seriously. Beyond being good re¬source stewards, there are financial implications to wasting water in CEA systems, making it important that operations identify opportunities to both reduce waste and partner with stakeholders (such as policymakers and utilities) to invest in water conservation technologies.

But even small measures, such as investigating drip irrigation lines and other plumbing for leaks, can help identify unnecessary costs: A nozzle or hose leaking one drop per second will waste 113 gallons per month, and a poorly adjusted evaporative cooling system can hundreds of gallons a day during summer.

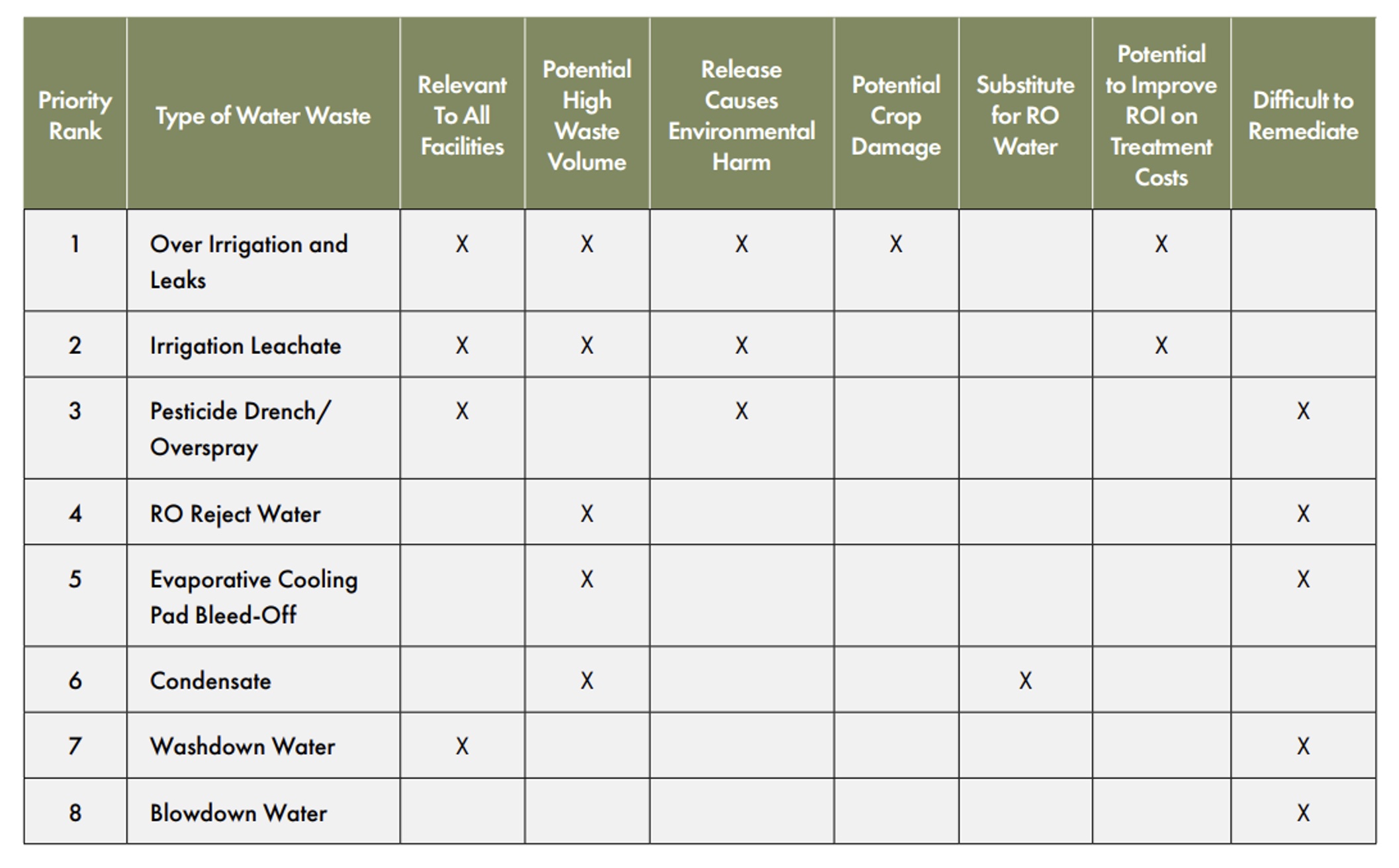

Here, RII and expert members identify some of the top water waste sources and offer tips and best practices on how to mitigate resource overuse and optimize your CEA operation.

Download Resource Innovation Institute’s Water Circularity Best Practices Guide here for more information, expert insights, and tips on improving CEA facility water usage, including how to design and build toward becoming a Minimum Liquid Discharge facility, as well as policy considerations for stakeholders to promote and utilities to adopt.

Over-Irrigation and Leaks

The top source of water wastage identified in RII’s Water Circularity Best Practices Guide is over-irrigation and leaks in irrigation/fertigation systems.

Over-irrigation and leaks can cause multiple issues in both hydroponic and container substrate-grown crops beyond financial costs. For example, over-irrigation in crops grown in horticultural substrate can cause root diseases, while leaks in recirculating hydroponics can waste fertilizer and lead to nutrient imbalances.

As mentioned, a single drop-per-second leak can cause more than 100 gallons of water to be wasted per month. For large-scale facilities, multiple nozzle failures can lead to massive waste, especially if a nutrient solution is involved. “A detailed study of actual costs from eleven ornamental plant growers in 2016 found that water sanitation costs $0.07-$1.00 per 1,000 gallons, while water-soluble fertilizers added $3.80,” per the Water Circularity Best Practices Guide.

In addition to manually inspecting fertigation lines as part of a commissioning review, Jeffery Martens, general manager at H2O Engineering, an RII member organization, recommends CEA facility operators install flow rate meters to monitor water use in key locations. “Put flow meters near water storage tanks, and from there [operators] can get an estimate of the tank turnover rate, and that’ll give them a general idea of how much water they’re using. If you have separate grow rooms, make sure to have a flow meter going to each grow room. By monitoring flow, you will have more precise fertigation and also monitor for possible leaks or irrigation plugging.” he says.

In terms of how and where to place flow meters to get the best results, “Follow the flow meter specifications closely. They should be in a continuous flow area with a straight length of pipe for accurate results,” Martens adds. “It’s much better for the meter to capture that [reading] accurately and consistently if you measure water flowing horizontally or up a vertical pipe, rather than going down a pipe going into a tank.”

Irrigation Leachate

The second-most common source of water wastage in CEA facilities is irrigation leachate–the runoff from nutrient solution applications. Henry Vangameren, Regional Marketing Manager with Priva (another RII member organization), says fertilizer costs have skyrocketed in recent years and that by recapturing, recycling, and reusing irrigation leachate, “you’re saving on water and you’re saving on fertilizer.”

He says Priva sees “a lot of operations, especially in cannabis, that are stripping this water with RO [reverse osmosis] just because they want to start with zero and then build that up again. They see that as a security measure,” to prevent disease from spreading. However, this leachate can rapidly foul RO systems, creating additional maintenance needs.

Rather than recirculating that leachate into an RO system to strip it of all electrical conductivity (EC), a common practice in hydroponic systems is to “reuse the nutrient solution for 5-10 days while “topping off” as needed by adding water and concentrated nutrient solution, usually to maintain a target EC and pH with an automated dosing system,” according to the Water Circularity Best Practices Guide.

Martens adds that “to get the most out of the irrigation leachate, you have to recover it before you blend it with anything else,” such as grey water from regular facility operations. CEA operators “should always look at the potential for reusing a water stream before they start blending it with another stream that could make it more difficult to remediate once they’ve been blended.”

Martens notes, to prevent pathogen spread, irrigation leachate is commonly disinfected with water treatment solutions designed to minimize the impact on crops. Work with a water treatment solutions company to pick the best system to fit your needs. Common treatment solutions, such as ozone, chlorine dioxide, electrochemically activated (ECA) water, copper ionization, peroxyacetic acid (acetic acid+ hydrogen peroxide), and/or UV light treatment can be applied. The Water Circularity Best Practices Guide highlights how the latter three can be used in combination to create a synergistic effect, but doing so can be costly as they require multiple systems.

As a general rule, it is best to use UV light treatments on water sources that are clearer in appearance, as opacity can limit the UV light’s penetration, reducing its effectiveness.

RO Reject Water

Reverse osmosis purification systems are more commonly utilized in indoor farm settings and are the most effective of the pressurized membrane purification systems. These include RO, microfiltration (MF), ultrafiltration (UF), and nanofiltration (NF) units. These technologies “differ in the pore size of the membrane and the pressure applied, with pores becoming smaller and pressure used increasing from MF→UF→NF→RO, with RO creating the most purified water,” per the Water Circularity Best Practices Guide.

Depending on the water quality and the RO system efficiency, an equal amount of waste water (brine) is rejected as pure water is created. A best practice is to minimize this brine waste by tuning the system’s recovery rate. Membrane filtration systems are typically specified for their recovery rate in percentage, the higher the value, the better.

Martens notes that water condition can be modeled, and in certain conditions the RO system can be tuned to improve recovery. “If you run an RO system at low recovery, you may be wasting a lot of water,” he says.

Evaporative Cooling Pad Bleed-Off Greenhouses with evaporative cooling pads generate a high volume of bleed-off water from these systems during warm periods, as more water is needed to maintain target temperatures. Reducing this bleed waste would greatly reduce the water a greenhouse facility uses.

One way to reduce the need for unnecessary cooling during warmer periods is to optimize environmental control systems integration, Vangameren says.

“One of the biggest issues that we face is systems that are disintegrated, meaning that it’s not a fully integrated system where the operator can not only see everything in one view but also how they are influencing each other. For example, the irrigation: it knows I’ve told it to irrigate at this time, but maybe the plants don’t need water at that point” based on factors like DLI and transpiration rates.

“When you integrate your system and you bring that all together into a complete environmental controller, a good system can anticipate what’s going to happen and when those plants will need something,” he says.

By reducing, remediating, and recycling water sources to the best of their abilities, indoor farms and greenhouse operations can maximize their overall facility efficiency and profitability.

Meet Our Members

Thank you to our members who participated in this blog. Read more about their organizations below:

Jeffery Martens is VP Sales and Service with H2O Engineering. He has 30 years of water treatment experience as a global business development and marketing executive. He has a long history of delivering innovative and successful antimicrobial and water reuse solutions. His recent efforts have focused on building filtration and ozone disinfection solutions for the challenging environment found in vertical farms. Jeff is a Chemical Engineer from the University of Michigan and has his master’s degree from Northwestern’s Kellogg School of Management.